Horizontal bench-top autoclaves Systec DX-Series

The Systec DX-Series, front-loading horizontal bench-top autoclaves, are available in 7 sizes with 25 to 200 liters of usable space. Compact on the outside, with ideal usable space on the inside. Each size offers optimal loading capacity for most standard medium bottles and Erlenmeyer flasks.

Two model ranges with different performance

Systec DX

For all laboratory applications even for sophisticated state-of-the-art sterilization processes. With all possibilities to add additional options for process optimization to enable validatable sterilization to be carried out.

Type

Chamber dimensions

Ø x depth (mm)

Chamber volume

in liters total / nominal

Techn. Drawings

Electrical connection for:

Systec DX-25 and Systec DX-45: Voltage 220–240 V, 50/60 Hz, 16A

Systec DX-65 to Systec DX-200: Voltage 380–400 V, 50/60 Hz, 16A

Other power supplies available on request. Country-specific deviations possible.

Standard Features

Systec dx

Integrated, separate steam generator

Housing, support frame and pressure vessel made of corrosion-resistant stainless steel

Temperature and pressure range 140 °C, 4 bar absolute pressure

The pressure vessel of the autoclave is made of corrosion-resistant stainless steel 1.4404 (AISI 316L)

Touch screen control

Number of sterilization programs

100

Code-secured access rights for changing parameters and further safety-relevant intervention

Internal memory capacity for storing up to 10 years of data backups

Timer for programmable start time

Additional temperature sensor in condensate exhaust

Flexible PT-100 temperature sensor (class A)

Additional temperature sensor in condensate exhaust

Special program for Durham tubes

Special program for destructive sterilization with fractional heating for more efficient venting

Calculation of F0 value

Waste water temperature is water-cooled and thermostatically controlled

Adjustable automatic opening of door at end of program

User account control (standard). The standard user account control has three permanently pre-configured and fixed user groups, each with one available user (Administrator, Operator or Supervisor).

Validation port for introducing measuring equipment

Integrated feature for comprehensive batch documentation, with export as PDF and CSV

Time synchronization with time server via network or internet

Available options

Extension of temperature and pressure ranges to 150 °C / 5 bar absolute pressure

Options for process optimization

Rapid cooling for efficient and safe cooling of liquids

Radial ventilator and Ultracooler to speed up the cooling process

Vacuum system to carry out the validated sterilization of solids and wastes in disposal bags

Superdry for drying solids (only in combination with optional vacuum system)

Exhaust air filtration (including condensate deactivation) for safe sterilization of hazardous biological substances

Options for documentation

Integrated printer for batch documentation

Save to Folder. Automatic data transfer via FTP/SFTP

Advanced CFR 21 Part 11 solution including AuditTrail. Enables run data to be electronically signed (so that it is tamper-proof). Documentation of all changes to the device and all alarm messages.

Personalized certificates for electronic signatures of run data (only applicable with the extended user account control)

Systec autoclaves are delivered ready for subsequent installation of all options.

Further options and special programs as well as baskets and inserts, transport and loading systems on request.

For further information on the options and accessories please click on Options“.

-

Design

State-of-the-art technology

The Systec autoclave is state-of-the-art, both in terms of its mechanical and electronic components, which together ensure a new level of quality in laboratory sterilization processes. Systec autoclaves therefore meet the requirements that will be placed on laboratory work in the future.All-round quality

The pressure vessel is made of corrosion-resistant stainless steel 316L (1.4404) and is easy to clean. An approved safety valve for excess pressure is included. The autoclave support framework and housing are also made of stainless steel. The highly efficient, high-quality melamine foam insulation material releases no particles; Systec autoclaves can be used under clean-room conditions.Dual sensors as standard

Temperature and pressure are controlled via an electronic pressure sensor, as well as a flexible temperature sensor in the chamber or in a reference vessel (with liquids). Systec DX-Series autoclaves also have an additional temperature sensor in the floor drain.Systec autoclaves are fitted with the following connections at the rear:

Demineralized water inlet for steam generation – Compressed air – Cooling water – Common outlet – RS-232 interface – Flexible power cord with CEE-plug – –= Standard–= Optional

All according to standards and regulations

Systec autoclaves are equipped as standard for sterilization temperatures up to 140 °C and steam pressures up to 4 bar absolute pressure.The Systec DX-Series models are also designed for higher steam pressure and higher temperatures: The pressure vessels are capable of withstanding a pressure of 5 bar (absolute pressure) at a sterilization temperature of 150°C as standard. The control, regulation, and safety components are also adapted to the higher maximum pressure and higher maximum temperature by this optional extension. Those who initially purchase a standard model can also have the extended performance range retrofitted at a later date.

-

Steam generation

Steam generation by steam generator

The steam generator is integrated into the autoclave housing but separated from the sterilization chamber.This has numerous advantages:

- No heating elements and no reservoir for dirty water in the chamber

- In conjunction with the stand-by pre-heating function, only 10 min. heating time to 121 °C with an empty chamber is required

- Improved air removal by suppressing the air to the bottom with its natural gravitation

- Quicker cooling as neither the hot water in the chamber nor the separate steam generator need to be cooled

- After cooling, steam is immediately available for the next sterilization run

Condensation of steam instead of removal

Exhaust steam is condensed automatically via a PT-100-regulated cooling system. This prevents odors and protects waste water piping that may be made of plastic. -

Operation

Touch screen Operation by Touch-Screen technology

Operation is easy and rapid via a large (5.7 inch) touch screen interface for direct reading. This innovation oers additional options and increased flexibility when working with the autoclave. For example, process data can be displayed numerically or graphically. 7 programs are pre-defined but can be expanded (up to 100) as required by the user. To create a new program, the user is guided through the process by a menu dialog. Every new program is automatically assigned to a permanent, unalterable name and can also be given an individual designation by the user. All process parameters can be individually altered.Pre-defined programs

1 Solids

2 Waste bags

3 Liquid waste

4 Liquids

5 Cleaning

6 Vacuum test*

7 Bowie-Dick test*These can be expanded to 100 sterilization programs.

* Only in combination with a vacuum device. -

Safety

Automatic door-opening system Automatic door-opening system

Easy but safe – on closing, the door is automatically locked by a circumferential ring system. A special lip seal made of heatresistant silicone provides reliable tightness; the more the steam pressure increases, the tighter the seal becomes – without the need for additional compressed air or other media! The door-locking system is temperature-controlled according to the safety requirements for electrical equipment for measurement, control, and laboratory use (DIN EN (IEC) 61010-2-040). The door remains locked as long as there is excess pressure in the chamber. The door and other parts of the pressure vessel and housing are made of stainless steel. The attractively designed front cover, which also incorporates the control panel, display and parts of the control processing system, is made of heatresistant, insulating plastic. There is no risk for the operator of coming into contact with hot components.

Automatic door opening

The autoclave door-opening works autonomously – either by pressing a button or automatically at the end of a program. A simple system but most useful in practice. Residual steam is exhausted automatically without intermission. Residual heat is used to dry the items being sterilized during a final short phase in the autoclave. Automatic door-opening is restricted to an angle of approx. 15°; this avoids possible contamination from the outside. This is especially useful when sterilized items have to remain in the autoclave for cooling and drying. Subsequently, for removing the sterilized items, the door can be completely opened manually. -

Standards and regulations

Systec autoclaves comply with the following standards and regulations:

Pressure vessel:

- 2014/68/EU Pressure Equipment Directive

- ASME Boiler & Pressure Vessel Code, Section VIII, Division 1

- China Stamp

Other guidelines:

- 2014 / 35 / EU Low Voltage Directive

- 2014 /30 / EU on Electromagnetic Compatibility

All autoclaves are CE marked.

We will be happy to provide a complete list of standards and summary of regulations on request.

-

Sterilization load and sterilization process

Sterilization load and sterilization process

Select the right process for every sterilization application

Several options are available that are necessary to obtain correct and validatable results and rapid cooling times, especially in the case of liquids. The options available depend on the items to be sterilized.

A validatable sterilization process of biological efficiency can only be obtained if the correct instrument configuration is used.

The table below provides help in establishing the desired configuration. Please ask our experts for additional advice!

Ventilation Cooling Drying Other Gravitation Simple pre-vacuum Pulsed excess pressure Fractionated pre-vacuum Conventional cooling with slow pressure release Rapid cooling system with support pressure Surface drying without vacuum Drying with subsequent vacuum + Superdry Exhaust air filtration Liquids + ? – – ? + ? – Unpacked non hollow items + + + + ? + Porous materials (filters, fabrics)– ? ? + – + Hollow items (pipette tips,empty glassware, tubes and hoses)– – – + – + Contaminated waste indestruction bags– – ? + – – + + Recommended procedure ? Possibly acceptable – Not possible

-

Sterilization of liquids

Sterilization of liquids

Heating up

Sterilization heating up The actual sterilization time of e.g. 15 minutes at 121 °C is only a fraction of the total time involved for an autoclave procedure. Especially in the case of sterilizing liquids, the heating up and cooling down phases are considerably longer.

The conventional procedure

In previously used conventional systems, even if the intended sterilization temperature has been reached within the autoclave, the liquids to be sterilized are often only at about 60-90°C; the temperature equilibrium time between chamber and liquids normally takes much longer.Up to 50 % shorter heat-up times as standard

Due to the combined temperature and pressure regulation, the chamber pressure is increased during the heat-up phase. The result: more rapid temperature equilibrium in the liquids and a shorter heat-up time.

Cooling

Conventional cooling vs. Rapid cooling The cooling process for liquids is also very slow; this is because, without active rapid cooling, the heat can only be reduced to below 100 °C by dissipating the heat via the chamber insulation by radiation (see diagram: conventional cooling). New system- and process technology makes it possible to substantially reduce the overall time required for the sterilization process (see diagram: rapid cooling).

Various optional rapid cooling systems enable the cooling times for liquids to be significantly reduced. This conserves culture media and makes for efficient utilization of the autoclave.

In addition to conventional cooling by regulated steam exhaust down to 100 °C and subsequent very slow self-cooling down to 80 °C, optional cooling systems for rapid cooling are available.

- Cooling with ambient air ventilation

- Mantle cooling with cooling water

- Mantle cooling with cooling water and support pressure

- Radial ventilator for air circulation and accelerated heat removal from the chamber

- Ultracooler

- Spray cooling with recirculated and recooled sterile water and support pressure

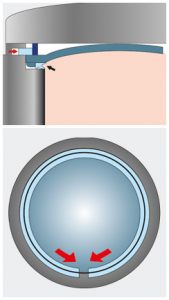

Mantle cooling with cooling water and support pressure

Mantle cooling with cooling water and support pressure During the entire sterilization process a flexible PT-100 temperature sensor monitors the temperature in a reference vessel. It is guaranteed that the sterilization period begins only once the sterilization temperature has been attained in the liquid to be sterilized. In accordance with relevant standards to prevent delayed boiling, the lid can only be opened once the temperature of the liquid has been reduced to at least 80 °C. The use of support pressure in the form of sterile-filtered compressed air during the cooling phase reliably prevents the culture medium from boiling.

Advantages:

- No loss of liquid due to boiling of the culture media

- Improved productivity from reduced cycle times and the full utilization of the filling volume in each bottle

- Prevention of delayed and over-boiling

- Prevention of the risk of bottles bursting during or after sterilization

- Prevention of re-contamination by the use of hermetically sealed bottles during sterilization

- Reduction of cooling time by up to 60 %

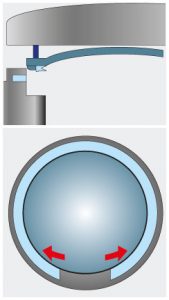

Radial Ventilator

Radial ventilator In conjunction with optional mantle cooling with cooling water and support pressure, the radial ventilator ensures accelerated removal of heat from the sterilization items to the cooled chamber mantle. The radial ventilator is placed in the door of the sterilization chamber so that the usable space in the autoclave is not reduced!

- The usable space in the autoclave is not reduced by the fan, as it is located in the door of the sterilization chamber.

- Air flow rate 71 m³/h

- Recooling times reduced by up to 70%

Ultracooler

Ultracooler In conjunction with optional mantle cooling with cooling water, support pressure and radial ventilator, it is possible to significantly reduce the recooling time and the entire sterilization process by integrating of the additional ultracooler heat exchanger. The Ultracooler is also placed in the door of the sterilization chamber near the radial ventilator so that the usable space in the autoclave is not reduced.

- The Ultracooler is placed around the radial fan in the chamber door so as not to reduce the usable space inside the chamber and to allow full loading.

- Up to 90% reduction in recooling times

- 15 to 60 minutes cooling time, depending on the load

-

Sterilization of liquids

Sterilization of liquids

Vacuum system

Typical solids are pipette tips (in boxes), empty glassware and porous materials such as filters or fabrics. The vacuum device effectively removes the air from solids, tubing, porous materials, and fabrics, allowing the steam to penetrate completely. The process includes a fractionated pre-vacuum phase in combination with the standard steam generator.

Vacuum system

Superdry – for drying solids

This optional accessory increases the drying efficiency for solids and porous materials such as filters and fabrics. Heat energy from the standard steam generator is transferred to the heating coils around the body of the sterilization chamber and is used for drying. Deep-vacuum drying using the optional vacuum device in conjuction with Superdry avoids the necessity for subsequent drying in a separate drying cabinet.

Superdry -

Sterilization of waste in disposal bags

Sterilization of waste in disposal bags

Vacuum system

For waste in bags, it is important to completely remove the air present in the sterilization load in order to ensure accurate, reproducible, and validatable sterilization.

Vacuum system The vacuum device is used for the highly effective removal of air from disposal bags so that the steam can also penetrate the items to be sterilized. This is achieved by means of a fractionated pre-vacuum in conjunction with the standard steam generator. This is the only way to achieve validatable sterilization of waste in disposal bags.

-

Sterilization of hazardous biological substances

Sterilization of hazardous biological substances

Exhaust air filtration with condensate inactivation

Exhaust air filtration For the sterilization of hazardous biological substances, Systec autoclaves can be fitted with an optional air exhaust filtration system. The autoclavable sterile filter, consisting of a filter cartridge with PTFE membrane of pore size 0.2 μm, is installed in a presure-proof housing and can be quickly changed at any time.

The filter is also automatically sterilized inline during the sterilization process, monitored by the PT-100 temperature sensor. The condensate is retained inside the pressure vessel during the heating and sterilization phases and thus also sterilized. Through air exhaust filtration and condensate inactivation, it is ensured that no microorganisms can escape before end of the sterilization phase.

-

Additional options

Extension of temperature and pressure ranges

Ready for tomorrow, today! The Systec DX-Series autoclaves are the first laboratory autoclaves of their kind to be suitable for higher temperatures at higher pressures. The pressure vessel is designed for 5 bar absolute pressure/150 °C as standard. With the optional temperature and pressure range extension, the control, monitoring, and safety components are also adapted to the higher pressure and temperature range. This option can also be retrofitted at a later date. -

Options for documentation

STANDARD: Internal memory

Internal memory The internal memory for process data uses the internal storage; this is part of the Systec PLC. The capacity is sucient to store process data over an average period of 10 years.

STANDARD: Elektronic data output

Elektronic data output The integrated documentation feature is used for comprehensive batch documentation and for exporting the electronic data as PDF or CSV via network interface or USB. The essential values of the individual program phases and process parameters are presented in a tabular overview, followed by a graph and a numerical table of the program sequence.

*the network interface requires the optional „Save to Folder“ feature for downloading the file to an FTP/SFTP server.

STANDARD: Backup feature

Backup feature The backup function (via USB) enables the user to save and restore:

- program lists and their parameters,

- complete backups of the device with the current device software and its databases.

The backup file is encrypted and thus protected against manipulation.

STANDARD: Real-time clock

Real-time clock The device has a real-time clock with automatic changeover to daylight savings time. Time, date and time zone can be set manually via the touch screen, the web server or automatically via the internet. A time server and an internet connection are required to automatically set the time.

- automatic summer/wintertime

- automatic leap year detection

OPTIONAL: Save to Folder

Save to Folder The „Save to Folder“ function automatically exports the current process log to a server after the cycle has been finished. The following server types are supported: FTP, SFTP, FTPS.

OPTIONAL: SCADA connection

Scada connection All relevant information (current values of defined analogue and digital inputs and outputs of a device, current process status, alarms) is transmitted by the autoclave using the OPC-UA protocol.

OPTIONAL: Printer

Printer An integrated printer is optionally available for documenting the program type, batch number, date, and time. The printout contains the essential information of a program cycle. It shows the basic parameter settings and the success or failure of a program cycle. The printout is created in the language that has been selected on the device.

OPTIONAL: Advanced CFR Part 11 solution

Advanced CFR 21 Part 11 solution Data can be downloaded from the autoclave as PDF and/or CSV (Excel) files*, using the USB or network interface**. Both the PDF and CSV files are electronically signed by the autoclave. This electronic signature is clearly assigned to the respective autoclave. It also indicates whether the exported files are valid or not. Any attempt of manipulation will result in the file being marked as invalid.

The advanced CFR 21 Part 11 solution also includes:

- Extended user account control. This includes an individual or global program list for each user, the assignment of the user to an individually created group (e.g. user, supervisor, administrator, cleaner, etc.) which has customizable rights.

- AuditTrail: All executed actions (e.g. changing parameters, starting or stopping sterilization programs) are documented and can be traced back to the respectice user and time stamp (date/time).

- There are up to five fields for electronic signatures. These are used to sign the exported PDF or CSV files on a PC (or any other device with the functionality to sign documents electronically).

* the network interface requires the optional „Save to Folder“ feature for downloading the file to an FTP/SFTP server

** only cycle data can be transferred via the network interface. -

Options for process optimization

Mantle cooling with cooling water and support pressure

Mantle cooling with cooling water and support pressure During the entire sterilization process a flexible PT-100 temperature sensor monitors the temperature in a reference vessel. It is guaranteed that the sterilization period begins only once the sterilization temperature has been attained in the liquid to be sterilized. The cooling temperature is also constantly monitored. In accordance with relevant standards to prevent delayed boiling, the lid can only be opened once the temperature of the liquid has been reduced to at least 80 °C.

Radial Ventilator

Radial ventilator In conjunction with optional mantle cooling with cooling water and support pressure, the radial ventilator ensures accelerated removal of heat from the sterilization items to the cooled chamber mantle.

- Reduction of cooling time by up to 70 %

Ultracooler

Ultracooler In conjunction with optional mantle cooling with cooling water, support pressure and radial ventilator, it is possible to significantly reduce the recooling time and the entire sterilization process by integrating of the additional ultracooler heat exchanger.

- Reduction of cooling time by up to 90 %

- Depending on the load, cooling times between 15 and 60 minutes can be achieved

Superdry – for drying solids

This optional accessory increases the drying efficiency for solids and porous materials such as filters and fabrics. Heat energy from the standard steam generator is transferred to the heating coils around the body of the sterilization chamber and is used for drying. Deep-vacuum drying using the optional vacuum device in conjuction with Superdry avoids the necessity for subsequent drying in a separate drying cabinet.

Vacuum system

Typical solids are pipette tips (in boxes), empty glassware and porous materials such as filters or fabrics. The vacuum system effectively removes the air from solids, tubing, porous materials, and fabrics, allowing the steam to penetrate completely. The process includes a fractionated pre-vacuum phase in combination with the standard steam generator.

-

Accessories

Loading baskets and inserts

Stainless steel wire mesh baskets and other accesories available upon request. All components are made of stainless steel and are cleanly welded.

Stainless steel wire mesh baskets and other accesories available upon request. All components are made of stainless steel and are cleanly welded.

Rack system

To fully utilize the available space in the chamber, especially when sterilizing small items, the autoclaves can be fitted with a rack system. The entire rack system or individual trays can be removed.

Loading table

There is a suitable loading table for every Systec DX-series autoclave. Precisely tailored to fit to the centimeter. With a standard loading table height of 72 cm (other heights available on request at no extra charge), the autoclave is in the right position for convenient handling. The lower shelf is practical and can be used, for example, to store the loading baskets.

There is a suitable loading table for every Systec DX-series autoclave. Precisely tailored to fit to the centimeter. With a standard loading table height of 72 cm (other heights available on request at no extra charge), the autoclave is in the right position for convenient handling. The lower shelf is practical and can be used, for example, to store the loading baskets.

Transport cart and transfer cart with Easy Load

Large autoclaves in particular can be easily and securely loaded using special transport and transfer carts. The items to be sterilized can either be placed directly on the transfer cart with rails or using a basket. The transport cart can be moved and docked to the autoclave and fixed in position. The handle can then be loosened to allow the transfer cart to slide into the autoclave on fixed rails.

Large autoclaves in particular can be easily and securely loaded using special transport and transfer carts. The items to be sterilized can either be placed directly on the transfer cart with rails or using a basket. The transport cart can be moved and docked to the autoclave and fixed in position. The handle can then be loosened to allow the transfer cart to slide into the autoclave on fixed rails.