Vertical floor-standing autoclaves Systec V-Series

The Systec V-Series of top-loading vertical autoclaves in 8 different sizes with 40 to 150 liters chamber volume is distinguished by its small footprint and high chamber capacity. Result: optimal loading capacity with most standard media bottles and Erlenmeyer flasks.

Two model ranges with different performance.

Systec VX

For all laboratory applications even for sophisticated state-of-the-art sterilization processes. With all possibilities to add additional options for process optimization to enable validatable sterilization to be carried out.

Systec VE

For basic laboratory applications and media sterilization. With limited possibilities to add additional options for process optimization.

Dimensions and performance

Chamber dimensions

Ø x depth (mm)

Chamber volume

in liters total / nominal

Techn. Drawings

Electrical connections for:

Systec V-40 and Systec V-55: 220-240 V, 50/60 Hz, 16A

Systec V-65 to Systec V-150: 380-400V, 50/60 Hz, 16A

Other voltages supplies are available on request.

Country-specific deviations possible.

Standard Features

vxSystec vx

veSystec ve

Integrated, separate steam generator

Internal heating elements within the autoclave chamber

Housing, support frame and pressure vessel made of corrosion-resistant stainless steel

Temperature and pressure range 140 °C, 4 bar absolute pressure

LCD display and fully automatic microprocessor control

Number of sterilization programs

12

Code-secured access rights for changing parameters and further safety-relevant intervention

Internal memory for storing up to 500 sterilization cycles

Timer for starting programs

Autofill: automatic demineralized water feed for steam generation

Flexible PT-100 temperature sensor

Additional temperature sensor in condense exhaust

Temperature holding function for liquids after program finish

Special program for Durham tubes

Calculation of F0 value

Special program for waste sterilization with pulsed heat-up for more efficient air exhaust

Water-cooled steam exhaust, thermostatically controlled

Programmable automatic door-opening on completion of program

RS-232 interface for external data transmission (network-compatible)

Available options

Touch-Screen control

Extension of temperature and pressure ranges to 150 °C / 5 bar absolute pressure (from chamber volume 65 liters and more)

Options for process optimization

Rapid cooling for efficient and safe cooling of liquids

Vacuum system for validatable sterilization of solids and waste materials in disposal bags

Superdry: for drying solids (only in combination with optional vacuum system)

Exhaust filtration (including condensate inactivation) for safe sterilization of hazardous biological substances

Options for documentation

Integrated printer for batch documentation

Systec ADS documentation software package f. comprehensive documentation

Documentation SD: data storage on SD card for up to 10,000 sterilization cycles and transmission of data to a PC

Systec ADS CFR documentation software package w. conform. to FDA 21 CFR Part 11**

AuditTrail: unalterable and traceable documentation acc. to FDA 21 CFR Part 11**

** for Systec VX-65 to Systec VX-150 in combination with a touch display

Systec autoclaves are delivered ready for subsequent installation of all options.

Further options and special programs as well as baskets and inserts, transport and loading systems on request.

For further information on the options and accessories, please click on "Options".

-

Design

High-tech engineering & all-around quality

Our autoclaves include pressure vessels made of stainless steel 316L (1.4404), with the housing and support frameworks made of steel as well. This makes the entire autoclave highly resistant to corrosion and very easy to clean. The housing and support framework are further enhanced with highly efficient top-quality Hanno-Tect for insulation. This material does not release any particles, allowing Systec autoclaves to satisfy the requirements of working under clean-room conditions.Dual sensors standard in all autoclaves

Systec autoclaves use a temperature sensor in addition to an electronic pressure sensor to monitor both the pressure and temperature during the entire sterilization process. The flexible temperature sensor can be used within the chamber or alternatively in a reference vessel containing liquids. In addition, Systec VX models feature a temperature sensor installed in the floor drain.Systec autoclaves are fitted with the following connections at the rear:

VX VE Demineralized water inlet for steam generation – – Compressed air – – Cooling water – – Common outlet – – RS-232 interface – – Flexible power cord with CEE-plug – – – = Standard– = Optional

Meeting all regulations and sterilization standards

Systec autoclaves are fit to withstand sterilization temperatures of up to 140 °C as well as steam pressures up to 4 bar absolute pressure.Systec V-Series autoclaves can be augmented for higher pressure and temperature ranges, allowing temperatures of up to 150 °C and pressure levels of 5 bar (absolute pressure). In addition to adapting the chamber, the optional accessories for extending pressure and temperature ranges also adapt all safety elements and control components to the higher range of temperatures and pressure levels. This option can even be retrofitted on Systec Autoclaves.

Exception: Extension of temperature and pressure to 150 °C / 5 bar absolute pressure is not available for Systec V-40 or V-55 systems.

-

Steam generation

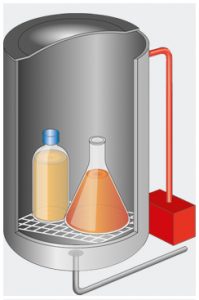

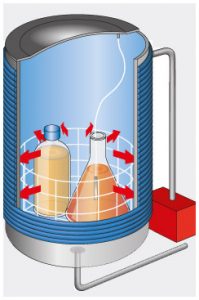

Steam generation via steam generator VX

The autoclave housing includes a separate steam generator.

This has various advantages:

No heaters or reservoirs of potentially contaminated water are required in the chamber.

- Thanks to the stand-by pre-heating function, an empty chamber can be heated to 121 °C within only 10 minutes

- Improved ventilation as gravity suctions the air downwards

- Cooling is sped up, as neither the steam generator nor the hot water inside the chamber requires additional cooling.

- Once the chamber is cooled, the next sterilization run can benefit from the generated steam.

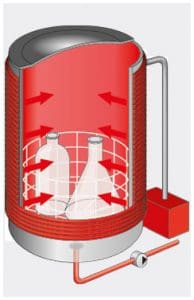

Conventional steam generation Conventional steam generation VE

This system of generating steam includes heating elements which are integrated into the lower part of the chamber. Water can be fed into the system manually. Autoclave models VE and VE can optionally be automatically fed with demineralized water with the DI-Water connection.

Condensing steam instead of removal VX VE

A PT-100-regulated cooling system is used to condense exhaust steam automatically. This prevents odors from developing and is especially useful for protecting plastic waste water pipes, if used. -

Operation

Operation via display Operation via Display

Systec V-Series autoclaves are controlled via a large, easy-to-read display and a membrane keypad with acoustic input confirmation. The layout of all input elements is logical and ergonomic and thus allows for convenient operation of the autoclave. Menus are available in English, Spanish, French, German and Italian – other languages can be included on demand.A specially developed microprocessor is responsible for carrying out all control functions. The processor controls not only the sterilization schedule but also steam pressure and temperature within the chamber. In addition, it manages all optional functions such as drying, rapid cooling as well as pre- and post-vacuum modes.

VX

1– 3 Solids

4 – 5 Waste bags

6 Liquid waste with regulated steam exhaust for cooling

7 Liquid waste with self-cooling

8 –10 Liquids with regulated steam exhaust for cooling

11 Liquids with self-cooling

12 Cleaning

13 Vacuum test**

14 Bowie-Dick Test**

15 – 25 Free for individual programming

VE

1– 3 Solids

4 – 5 Waste bags

6 Liquid waste with regulated steam exhaust for cooling

7 Liquid waste with self-cooling

8 –10 Liquids with regulated steam exhaust for cooling

11 Liquids with self-cooling

12 Cleaning* All programs can be individually parametered.

** Only in combination with vacuum system.

Touch-screen technology Optional operation by Touch-Screen technology for all Systec VX models from 65 liter chamber volume

Thanks to a large (5.7 inch) optional touch-screen interface, controlling the autoclave can be made even easier. In addition, this option adds increased flexibility during autoclave operation and offers additional options for using the system, such as displaying process data numerically or graphically. Up to 100 different sterilization programs can be stored within the system, including seven pre-defined standard programs already included. Users can configure new programs themselves, defining and altering all available process parameters individually. Users are guided step-by-step through the entire process via the dialog menu. Every new program added is automatically given a permanent, unalterable name. In addition, a designation freely chosen by the user can be assigned to the program.Pre-defined programs

1 Solids

2 Waste bags

3 Liquid waste

4 Liquids

5 Cleaning

6 Vacuum test*

7 Bowie-Dick test*These can be expanded to 100 sterilization programs.

* Only in combination with a vacuum device. -

Safety

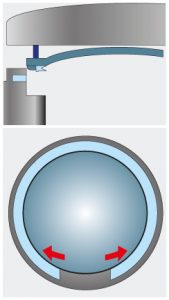

Automatic door-opening system Automatic door-opening functionality

Systec autoclave chamber doors are locked automatically, utilizing a circumferential ring system* which engages when the door is being closed. The chamber is sealed using a special seal made of highly heat-resistant silicone; the seal tightens as more pressure is built inside the chamber. This occurs automatically, without requiring additional compressed air.In full accordance with modern regulations for pressure vessels such as DIN EN (IEC) 61010-2-040, the door-locking mechanism is controlled by the interior temperature. Thus, the door remains firmly locked and sealed until all excess pressure within the chamber has dissipated. The door as well as various other elements of the housing and vessel are built using stainless steel and clad in an aesthetically pleasing front cover is made of insulated plastic that is highly resistant to heat. The same material is used for the control panel, display as well as parts of the control processing system. This prevents operators from coming into contact with heated surfaces.

The standard method of opening Systec autoclave doors is to press the corresponding opening button. Alternatively, VX and VE models can also be programmed to open automatically once the sterilization process has ended. This is very convenient for everyday use, as it allows residual steam to be vented automatically. Any residual heat within the chamber itself can be utilized to dry the items which have just been sterilized.

The standard method of opening Systec autoclave doors is to press the corresponding opening button. Alternatively, VX and VE models can also be programmed to open automatically once the sterilization process has ended. This is very convenient for everyday use, as it allows residual steam to be vented automatically. Any residual heat within the chamber itself can be utilized to dry the items which have just been sterilized.* Exceptions: In models V-40 and V-55, the door is closed by means of a bolt.

-

Standards & regulations

Systec autoclaves comply with the following standards and regulations:

Pressure vessel:

- 2014 / 68 / EU Pressure Equipment Directive

- ASME Boiler & Pressure Vessel Code, Section VIII, Division 1

- China Stamp

Other guidelines:

- 2014 / 35 / EU Low Voltage Directive

- 2014 /30 / EU on Electromagnetic Compatibility

All autoclaves are CE marked.

We will be happy to provide a complete list of standards and summary of regulations on request.

-

Sterilization load and sterilization process

Sterilization load and sterilization process

Selecting the correct process for each sterilization run

There is a variety of sterilization options available that may be required to obtain reliable and validatable sterilization results, as well as rapid cooling times, especially when it comes to sterilizing liquids. Which options are available depends on the items that are to be sterilized. A validatable, biologically efficient sterilization process can only be ensured if the autoclave is configured correctly.The table shown below can help with configuring your autoclave – however, we recommend consulting with our experts before configuring sterilization programs.

Ventilation Cooling Drying Other Gravitation Simplepre-vacuumPulsed excesspressureFractionatedpre-vacuumConventionalcooling withslow pressurereleaseRapid coolingsystem withsupportpressureSurface dryingwithoutvacuumDrying withsubsequentvacuum+ SuperdryExhaust airfiltrationLiquids + ? – – ? + ? – Unpacked non hollow items+ + + + ? + Porous materials (filters, fabrics)– ? ? + + Hollow items (pipette tips,empty glassware, tubesand hoses)– – – + – + Contaminated waste indestruction bags– – ? + – – + + Recommended procedure ? Possibly acceptable – Not possible

-

Sterilization of liquids

Sterilization of liquids

Heating up Heating up

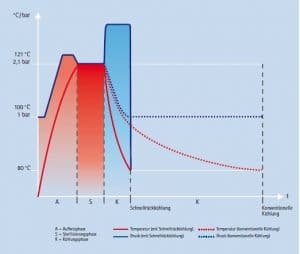

The entire autoclave procedure typically includes only a small fraction of time dedicated to actual sterilization – for example, when sterilizing at 121 °C, only about 15 minutes are typically spent on sterilizing. While sterilizing liquids, in particular, phases of heating up the chamber and cooling it down again make up a considerably longer part of the sterilization procedure.Conventional sterilization procedures

Most conventional autoclaves fail to properly sterilize liquids, as these typically reach only about 60 to 90 °C despite the chamber itself having already reached sterilization temperatures. This is because the temperature for sterilization within the chamber is reached quickly, while liquids need additional time for their temperature to equalize.Up to 50 % shorter heat-up times as standard

Thanks to the regulation of pressure as well as temperature at the same time, the pressure within the vessel is evenly increased during the initial heat-up phase. As a result, temperature equalization between liquids and the chamber itself is sped up, resulting in overall shorter heat-up times.

Conventional cooling vs. rapid cooling Cooling

Liquids are also very slow to cool down, as, without active rapid cooling, temperatures within the chamber can only drop below 100 °C via a process of dissipating the built-up heat as radiation via the chamber insulation (see diagram: conventional cooling).However, the overall time necessary for sterilization processes can be reduced substantially by using the new system and process technologies, potentially saving many hours during long sterilization processes (see diagram: rapid cooling).

Systec autoclaves offer numerous cooling functions for sterilizing liquids, including optional rapid cooling systems which reduce the time required for cooling liquids significantly.

Systec autoclaves can be cooled by conventional means, using a regulated steam venting procedure that cools the machine down to a temperature of 100 °C, after which the chamber cools down more slowly to about 80 °C by itself. Alternatively, they can include various options for rapid cooling, such as:

- Cooling with ambient air ventilation

- Mantle cooling with cooling water

- Mantle cooling with cooling water and support pressure

- Radial ventilator for air circulation and accelerated heat removal from the chamber

- Ultracooler

- Spray cooling with recirculated and recooled sterile water and support pressure

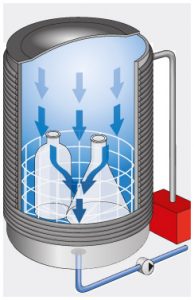

Mantle cooling with cooling water and support pressure Mantle cooling with cooling water and support pressure VX VE

A flexible PT-100 temperature sensor is used throughout the entire cooling procedure to monitor the temperature within a vessel that is filled with liquid as a reference measurement. The sterilization period thus begins only once the temperature required for sterilization has been achieved in the actual liquid instead of inside the chamber.The temperature of any subsequent cooling processes is monitored as well. Additionally, in order to protect the sterilized items from delayed boiling, the lid of the container can be opened only once the temperature inside of it is equal to or lower than 80 °C, according to industry standards. To prevent the liquid from boiling, support pressure is applied during the cooling-down phase using compressed air which has been filtered to be sterile.

Advantages:

- No liquid can be lost during sterilization, as boiling is prevented

- Cycle times are reduced in order to fully utilize the volume of each bottle, improving productivity in the process

- Prevents delayed boiling and overboiling

- Prevents bottles from bursting due to the heat of sterilization

- Using hermetically sealed bottles prevents re-contamination after sterilization

- Reduces cooling times by up to 60 %

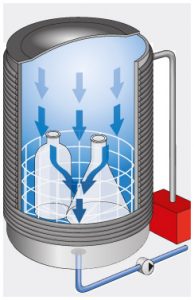

Radial ventilator Additional Radial Ventilator VX VE

Combined with an optional cooling system which cools the chamber mantle with water while applying support pressure, a radial ventilator can ensure that heat is transported quickly from the sterilized items to the chamber mantle where it is cooled down.- In order to not reduce the space available within the autoclave, the ventilator is mounted within the chamber door.

- Typical ventilation performance: 71 m3/h

- Reduces time for cooling by 70 % or less

Ultracooler Ultracooler VX VE

Combined with optional mantle cooling with cooling water, support pressure as well as a radial ventilator, an Ultracooler heat exchanger can reduce cooling times significantly, thus speeding up the process of sterilization as a whole.- The Ultracooler is mounted inside the chamber door, surrounding the radial ventilator. This requires no additional space within the chamber.

- Can achieve cooling times of 15 to 60 minutes, depending on the type and number of items which are to be sterilized.

- Reduces time for cooling by up to 90 %

-

Sterilization of solids

Sterilization of solids

Vacuum system Vacuum system VX

Solids, including but not limited to empty glassware, pipette tips in boxes as well as fabrics and porous materials like filters all require air to be removed before sterilization can commence.A vacuum system removes air from solids and hollow items such as tubing, as well as from porous materials and fabrics, which allows the sterilizing steam to cover their entire surface area. This is ensured by utilizing a phase during which a fractionated pre-vacuum is created, combined with the steam generator integrated into the autoclave.

Superdry Drying solids wit Superdry VX

The optional Superdry accessory increases drying efficiency porous materials, solids and fabrics. With this system, the heating coils wrapped around the sterilization chamber receive heat from the steam generator in order to facilitate drying. By using deep-vacuum drying with the optional vacuum device combined with Superdry, you can avoid having to dry sterilized materials in specialized drying cabinets. -

Sterilization of waste in disposal bags

Sterilization of waste in disposal bags

Vacuum system Vacuum system VX

When sterilizing waste bags, all air needs to be removed in order to ensure validatable sterilization results which can be reproduced every time.The vacuum device effectively removes the air from disposal bags, allowing the steam to penetrate completely. The process includes a fractionated pre-vacuum phase in combination with the standard steam generator.

-

Sterilization of hazardous biological substances

Sterilization of hazardous biological substances

Exhaust air filtration Exhaust air filtration & condensate inactivation

In order to sterilize hazardous substances, an optional system for filtering air exhaust is available for Systec autoclaves. Its heat-resistant sterile filter is installed in a pressure-proof housing, making it easily accessible. The filter consists of a cartridge with a PTFE membrane – with a pore size of 0.2 μm. The filter is itself sterilized over the course of each sterilization run. The PT-100 temperature sensor also monitors the filter.

During the phase of heating up the chamber and the actual sterilization phase, condensation is automatically retained and sterilized inside the vessel. All existing microorganisms are eliminated effectively, as air exhaust filtration systems and condensate inactivation methods prevent them from escaping during sterilization. This also ensures that hazardous liquids or gases cannot be released but are sterilized and filtered out instead.

-

Additional options

Touch-Screen

from 65 liters chamber volume

Operation is easy and rapid via a large (5.7 inch), highly visible touch screen interface. The process data can be displayed numerically or graphically. 7 programs are pre-defined but can be expanded (up to 100) as required by the user.To initiate a new program, the user is guided through the process by menu dialog. Every new program is automatically allocated a permanent, unalterable name and can also be given an individual designation by the user. All process parameters can be individually altered.

Touch screen

Temperature and pressure range extension VX

From 65 liters chamber volume

The pressure vessel of the Systec V-Series autoclaves is designed for operations at 150 °C and 5 bar absolute pressure. Optional temperature and pressure range extension accessories adapt all control and safety components to the higher temperature and pressure. This option can be retrofitted.Exception: Extension of temperature and pressure to 150 °C / 5 bar absolute pressure is not available for Systec V-40 or V-55 systems.

-

Options for documentation

Printer Printer VX VE

Systec autoclaves can optionally include an integrated printer for the purpose of documenting the sterilization process. Metrics which can be documented include date and time, pressure and temperature, activated program type and batch number as well as sterilization progress and phase.

Systec ADS Documentation Software Systec ADS documentation software package VX VE

Systec autoclaves include RS-232 interface and are thus able to be connected to any available Ethernet networks or a laptop or desktop PC via converters. Special documentation software allows users to document all process data such as the exact pressure and temperature ranges, sterilization time as well as sterilization phase. This documentation may also include relevant diagrams.

SD card SD card for batch documentation* VX VE

An optional integrated SD card slot can be used to document up to 10,000 cycles*. This includes a SD memory card (1024 MB). Thanks to this SD card, all recorded data can be processed using the Systec ADS software.* only combined with the Systec ADS software (optional).

Systec ADS CFR documentation software FD21 CFR Part 11 Systec ADS CFR documentation software package with conformity to FDA 21 CFR Part 11 VX

This optional software package can be used for documentation in Systec VX autoclaves (only models with a minimum of 65 liters sterilization chamber volume) featuring the optional display with touch-screen capabilities. Process flow and AuditTrail data can simply be downloaded from the machine, thus conforming to the regulations set out in FDA 21 CFR Part 11. This Systec software is able to process the data gathered by the autoclave numerically or as graphical representations.

AuditTrail AuditTrail VX

AuditTrail is used for administration purposes, allowing you to set up and manage user accounts. Using AuditTrail, you can specify privileges to users along five different authorization levels. Rights to access specific sterilization programs may be given to users on an individual basis, meaning a user must use their username and password to log in in order to be able to use only the specific programs they have been allowed to use. All actions carried out, such as changing program parameters or starting and stopping a sterilization program, are automatically documented. Thus, it is possible to track each action back to the user responsible using a time stamp which includes the date and the time. All data which is generated by user actions or via automatic documentation is protected and marked with an electronic signature unique to the respective user and protected against manipulation. -

Options for process optimization

Mantle cooling with cooling water and support pressure Mantle cooling with cooling water and support pressure VX VE

A flexible PT-100 temperature sensor is used throughout the entire cooling procedure to monitor the temperature within a vessel that is filled with liquid as a reference measurement. The sterilization period begins only once the temperature required for sterilization has been achieved in the actual liquid instead of inside the chamber.The temperature of any subsequent cooling processes is monitored as well. Additionally, in order to protect the sterilized items from delayed boiling, the lid of the container can be opened only once the temperature inside of it is equal to or lower than 80 °C, according to industry standards. To prevent the liquid from boiling, support pressure is applied during the cooling-down phase using compressed air which has been filtered to be sterile.

Radial ventilator Additional Radial Ventilator VX VE

Combined with an optional cooling system which cools the chamber mantle with water while applying support pressure, a radial ventilator can ensure that heat is transported quickly from the sterilized items to the chamber mantle where it is cooled down.

Ultracooler VX VE

Combined with a water-cooled mantle, support pressure as well as a radial ventilator, an Ultracooler heat exchanger can reduce cooling times significantly, speeding up the process of sterilization as a whole.

Superdry Superdry – for drying solids VX

The optional Superdry accessory increases drying efficiency porous materials, solids and fabrics. With this system, the heating coils wrapped around the sterilization chamber receive heat from the steam generator in order to facilitate drying. By using deep-vacuum drying with the optional vacuum device combined with Superdry, you can avoid having to dry sterilized materials in specialized drying cabinets.

Vacuum system Vacuum system VX

The vacuum device effectively removes the air from solids, tubing, porous materials, and fabrics, allowing the steam to penetrate completely. The process includes a fractionated pre-vacuum phase in combination with the standard steam generator. -

Accessories

Loading baskets and inserts

Stainless steel wire mesh baskets, stackable

Lifting device for heavy items

The electrically operated device with swivel arm facilitates the loading and unloading of heavy items. A mobile control panel with push-button operation makes for ease of use. The device is attached to the side of the autoclave. The swivel arm has a special grip for the baskets that remain stable even under loading conditions.